Enhancing Efficiency with Lean Six Sigma

At Medvantx, we believe in fostering an environment where career and personal development are part of our company standard. One of the ways we support our employees in their career, and to ensure our pharmacy operates productively, is by enhancing efficiency with Lean Six Sigma Yellow Belt Certification program. This program is designed for cultivating excellence throughout individuals and departments, equipping teams with essential skills in quality management, enabling them to contribute to process improvement projects and drive quality efficiency across the organization.

Six Sigma is a quality management process that aims to improve product and service production by reducing errors and defects, increasing efficiency and quality, and minimizing variation. Achieving Six Sigma quality level means having only 3.4 defects per million opportunities. Lean Six Sigma adds an additional layer of waste reduction as a key goal, utilizing data-driven decision-making to enhance processes.

Key Lean Six Sigma Tools Used

- DMAIC (Define, Measure, Analyze, Improve, Control)

- Value Stream Mapping

- Root Cause Analysis (RCA)c

- Failure Mode and Effects Analysis (FMEA)

- 5s Methodology

- Statistical Process Control (SPC)

Why We Do This

Cultivating excellence in Lean Six Sigma brings numerous benefits such as reduces defects and errors in production, improves process efficiency and reduces waste and ensures compliance with industry and company regulations. During this training, employees also review enhances in customer satisfaction, reducing costs and increasing profitability and encourages continuous improvement. ” CEO Prasanna Parthasarathy shares, “We’re energized by the pursuit of excellence at Medvantx! It’s who we are! Six Sigma is our launchpad, helping our amazing team deliver the absolute best for our customers and patients, every single day. We’re making a positive impact, and our customers are loving it!”

Certification Levels

Six Sigma offers various belts that signify different levels of expertise and responsibility:

- White Belt: Basic understanding of Six Sigma processes.

- Yellow Belt: Supports projects and participates as a core team member.

- Green Belt: Leads small projects and supports major process improvements.

- Black Belt: Leads major process improvements and oversees company-wide strategies.

- Master Black Belt: Oversees company-wide strategies and mentors other belts.

Medvantx partners with MoreSteam to provide flexible, self-paced online courses. Participants engage in hands-on practice through interactive simulations (EngineRoom) and receive group support via Teams group chat, where they can discuss challenges and pose questions. Knowledgeable and supportive Black Belt leadership, such as Bud Lawrence, guides participants through their training.

Highlighted Projects

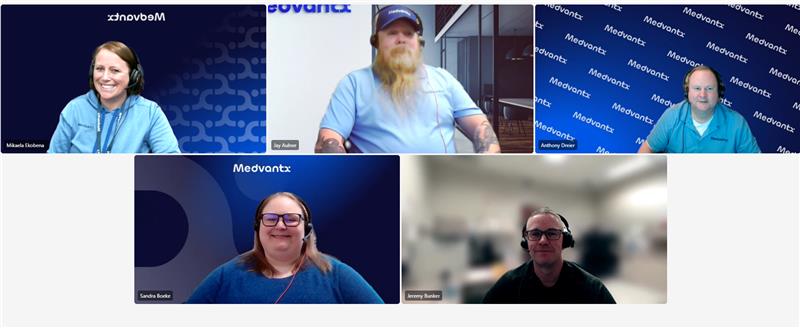

We are proud to announce the graduation of 5 employees from the program. Our graduates have worked on impactful projects, including Jeremy Bunker, Production Supervisor, who focused on step reduction in manufacturer cold chain packing. Jay Aulner, Warehouse Supervisor, worked on internal and external trash bin consolidation and bailer implementation. Sandra Boeke, Order Entry Manager, formalized the entry of manufacturer orders to reduce time waste. Anthony Dreier, Customer Experience Communications Lead, automated data entry into refill forms for faxing to doctors. Mikaela Ekobena, AD Pharmacy Production, optimized stocker and packer workflows to reduce movement during manufacturer cold chain packing.

Sandra Boeke shares her experience: “The Yellow Belt Certification has been transformative for me. It has equipped me with the tools to formalize the entry of manufacturer orders, reducing time waste and improving overall efficiency.” Mikaela Ekobena reflects on her projects: “Realigning stocker and packer workflows during manufacturer cold chain packing has significantly reduced movement and increased productivity. The certification has enhanced my ability to identify and eliminate waste, leading to better outcomes for our team.”

Featured left to right: Mikaela, Jay, Anthony, Sandra, Jeremy.

At Medvantx, we are committed to continuous improvement and empowering our employees to achieve their full potential. The Six Sigma Yellow Belt Certification program is just one of the many ways we support career and personal development, ensuring our team is equipped to drive excellence in everything we do. To learn more about Medvantx career development, click here.